In this article, we are going to examine the details of TDF ducts in the galvanized ducting system .

The best material for the ventilation system after various reviews over the past years is still galvanized sheet .

Due to the high price of galvanized sheet, economic saving in this matter has been of great importance, which is the concern of respected employers .

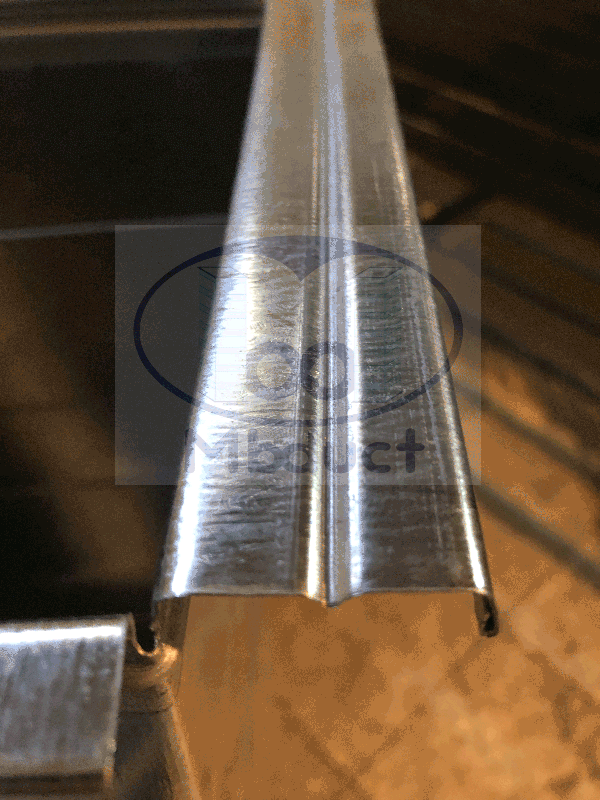

Definition of TDF duct

tdf is an abbreviation of transverse duct flange .

In the ventilation industry, ducts are called ducts where the galvanized duct itself has been turned into a flange

And the external flange is not used for connection.

TDF duct

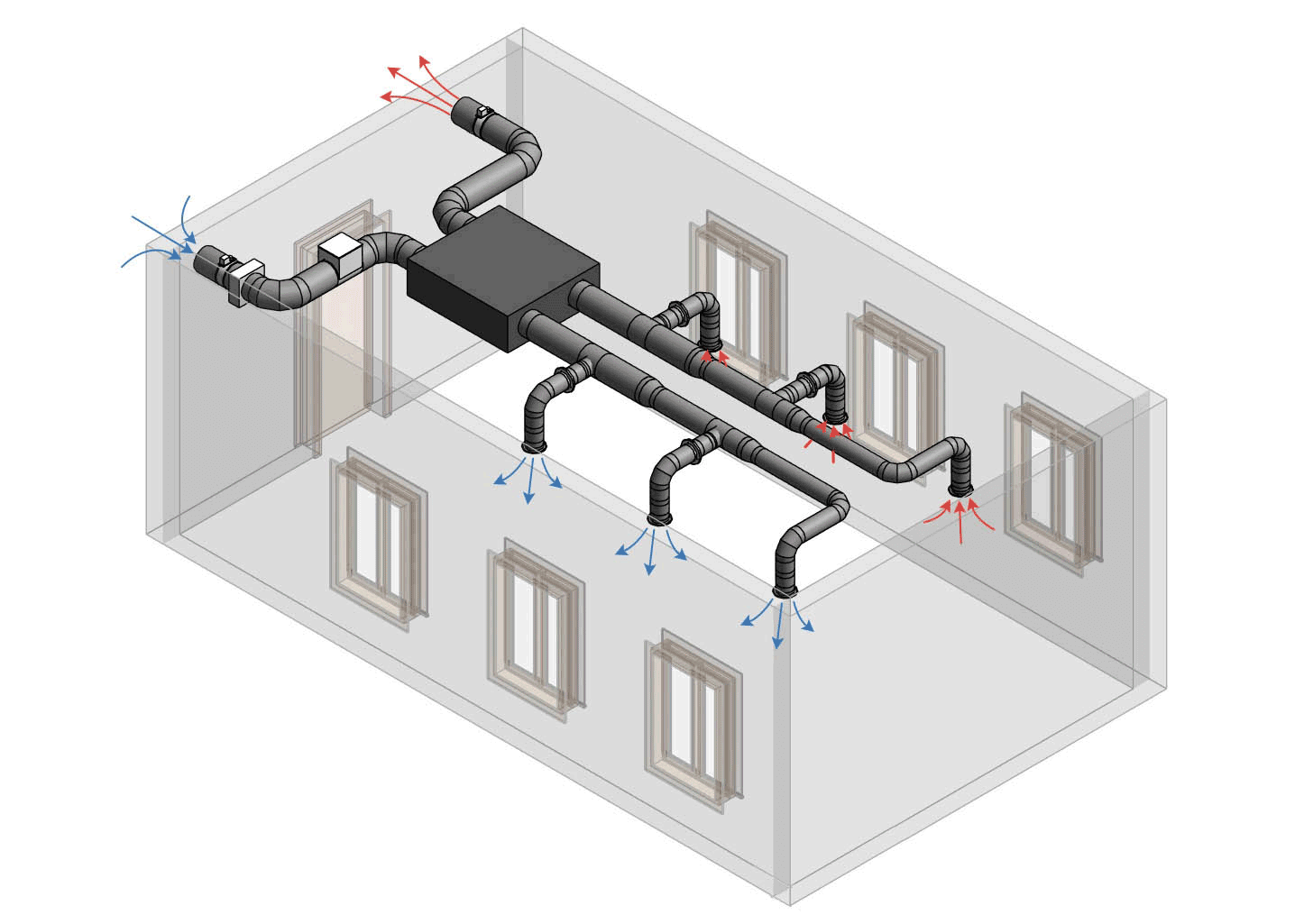

Rectangular galvanized ducts that are used in the ventilation industry today

From the past until now, it has always been tried by reducing the consumption of materials and also reducing the seams caused by connecting the ventilation ducts to each other , Avoid wasting energy

Therefore, many designs and ideas came to the market, but none of the materials could transmit air as well as the galvanized sheet.

Therefore, the galvanized sheet is still the best air transfer option in the ventilation industry.

.The TDF duct system reduces the cost of construction and production and increases the speed by using up-to-date technology

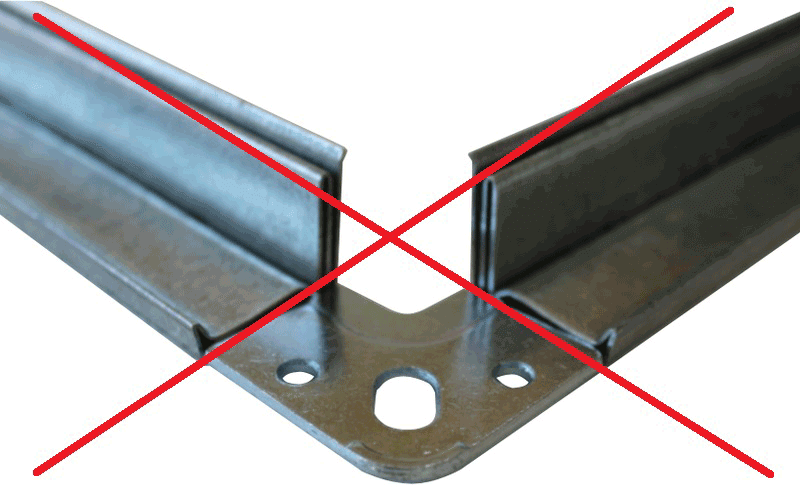

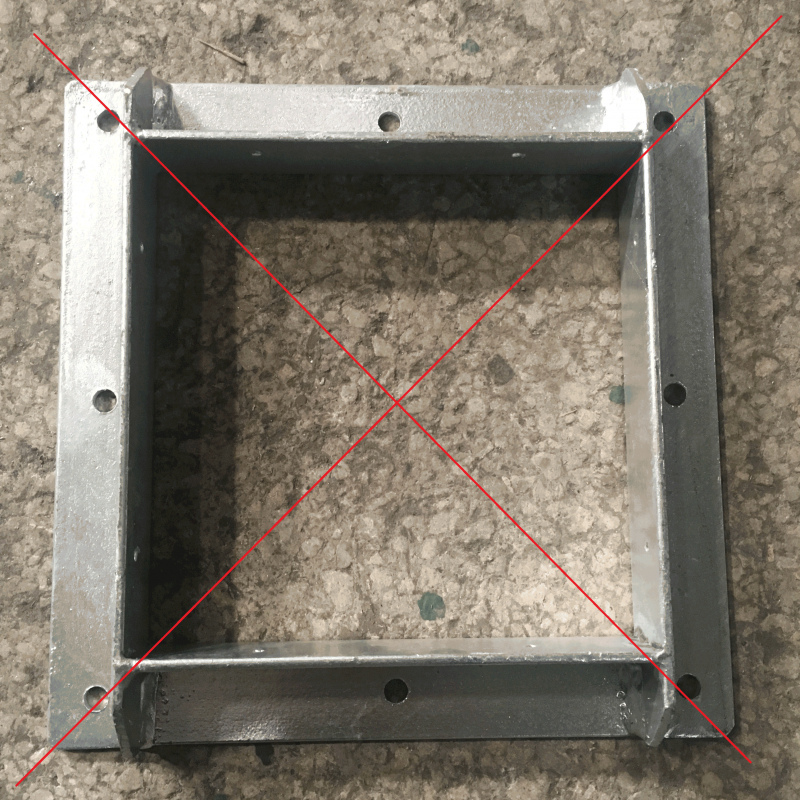

Disadvantages of iron flange ducts and galvanized flanges

In the past, HVAC (Heating, Ventilation, and Air Conditioning) ductwork and flanges were almost entirely crafted manually and put into use. Consequently, they suffered from time and numerous errors. Furthermore, they caused significant acoustic pollution.

Today, given the importance of HVAC systems, flanges, fresh air, positive pressure, and negative pressure ducts within buildings, the effective role of ductwork is felt more than ever before.

Considering the substantial financial cost of galvanized ductwork in residential, commercial, industrial, and other projects, the creation and production of an innovative, cost-effective, and high-quality system that contributes to reducing financial expenses and project completion time for clients is highly desirable.

We are proud to announce that our industrial group, MB Duct (Mbduct), has introduced and presented an advanced system, the Transverse Duct Flange (TDF), which significantly aids in enhancing the quality, reducing costs, and facilitating the construction of your civil projects, dear valued clients.

TDF Duct Benefits

- Flange Elimination

The most significant advantage of TDF duct, when compared to traditional systems, is the elimination of flanges (both iron and galvanized).

| Disadvantages of Galvanized Flanges | Disadvantages of Iron Flanges |

| High cost, increased time consumption, air leakage, screw and bolt consumption, and the use of clips. | High cost, prolonged time consumption, need for corrosion-resistant screws and bolts, non-combustible thread and tape, duct weight increase. |

In the innovative Mbduct system, the sheet itself is transformed into a flange using fully automated machinery.

Both ends of the duct sheet are converted into flanges by the fully automated machine, resulting in the lowest air leakage coefficient from the duct joints and, figuratively speaking, creating an air-tight seal.

-

Reduced Weight of Duct

The elimination of flanges has played a significant role in reducing the weight of the duct, which means:

- Reduced structural load and less need for supporting structures, leading to a lighter overall structure.

This aspect contributes to both time and cost savings.

-

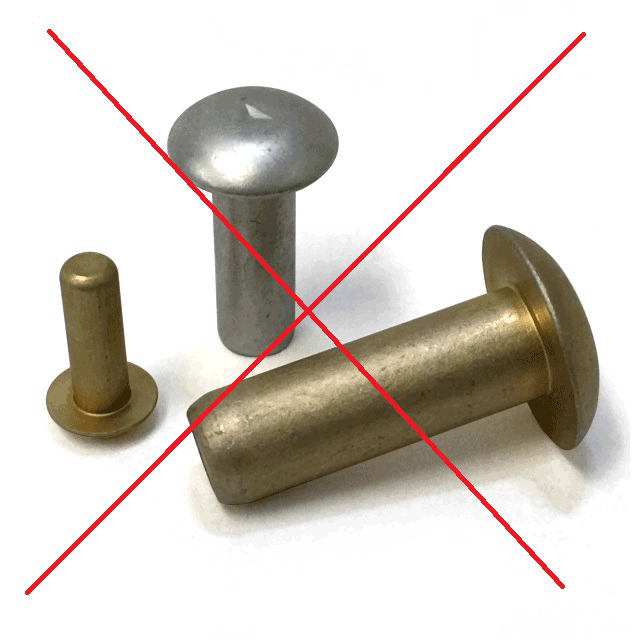

Reduction in Screws, Bolts, and Elimination of Rivets

The utilization of screws and bolts in the MB Duct (TDF) system experiences a significant reduction compared to other systems.

For iron flanges, rivets are required for connection, while galvanized flanges necessitate the use of self-tapping screws or bolts. In the Mbduct (MB Duct) ducts, all of these elements are eliminated.

-

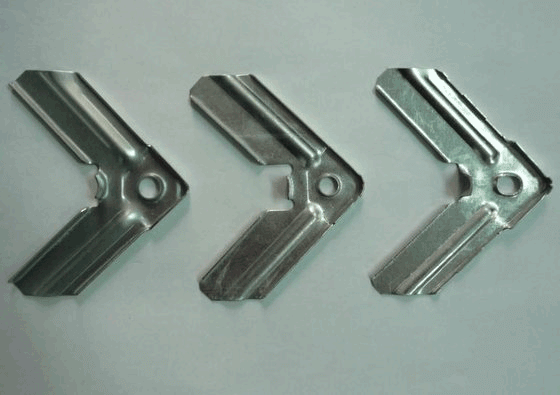

Utilization of Special Clips

In MB Duct ducts, due to the use of specialized clips, less time is wasted during installation and implementation.

-

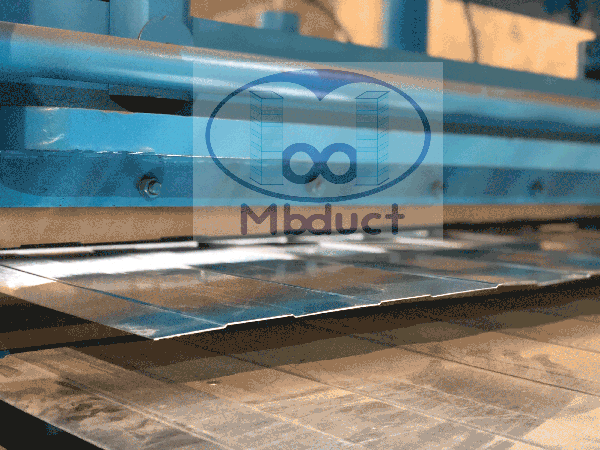

Unique Forming Design

Another advantage of these ducts is the distinctive sheet forming, which is in the form of a shadow line or louver.

In this design, due to the created form, the sheet’s strength is enhanced, resulting in reduced vibrations and deformations.

-

Reduction in Galvanized Sheet Size

One of the most important factors in sheet forming within MB Duct is the reduction in sheet thickness.

In this system, using various dimensions, one or two sizes can be reduced from the calculated amount.

This leads to a decrease in financial costs and the overall load of the duct system for the client.

| Type of ducted ventilation system | The thickness of the sheet used |

| Traditional | Fits the design |

| TDF duct or self flange (mbduct) | 1 to 2 sizes smaller than the design |

-

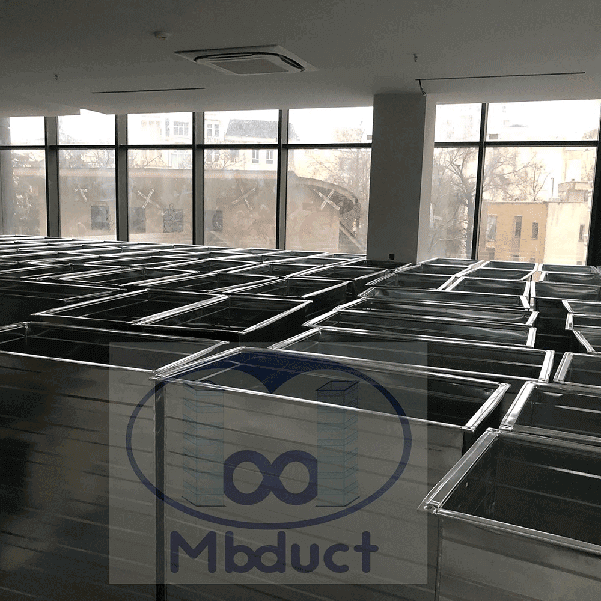

Aesthetic Appeal

MBDuct ducts, due to their enhanced visual appearance, serve as a suitable choice for projects where exposed ductwork is implemented.

-

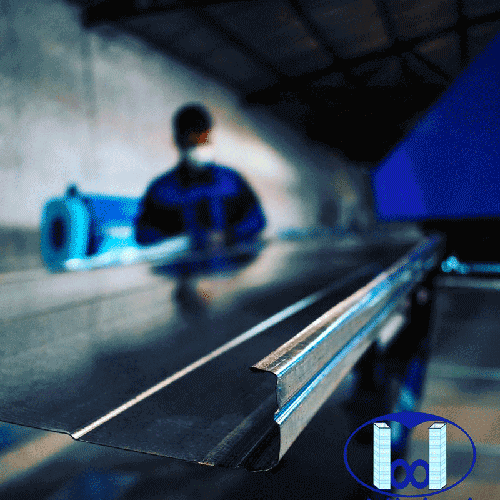

High Speed and Precision in Cutting

Another advantage of using these types of ducts is the high speed and precision during cutting and fabrication of these ducts.

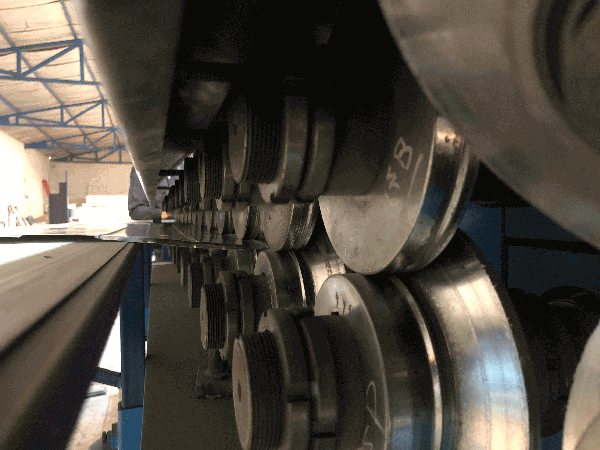

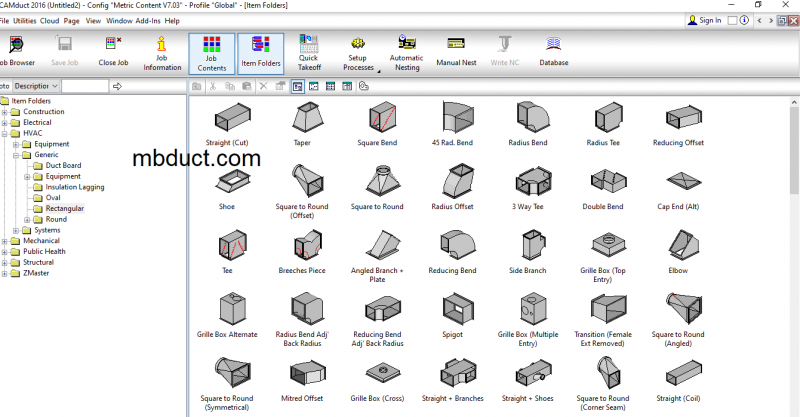

In our facility, we employ fully automated machinery such as roll forming, CNC plasma, and flange machines, operating at the highest speed and precision in accordance with the latest global ventilation standards for manufacturing and cutting.

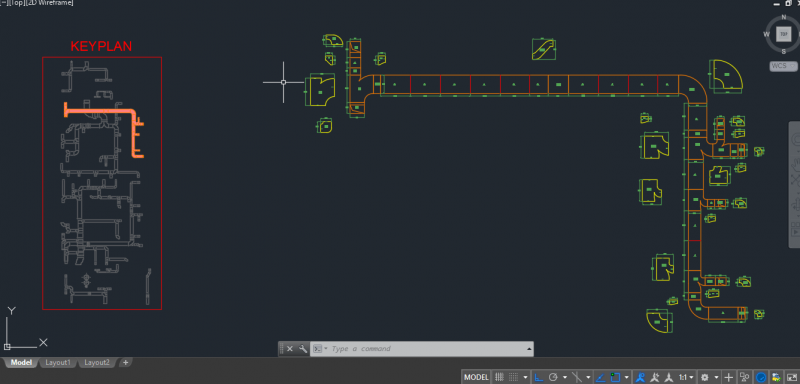

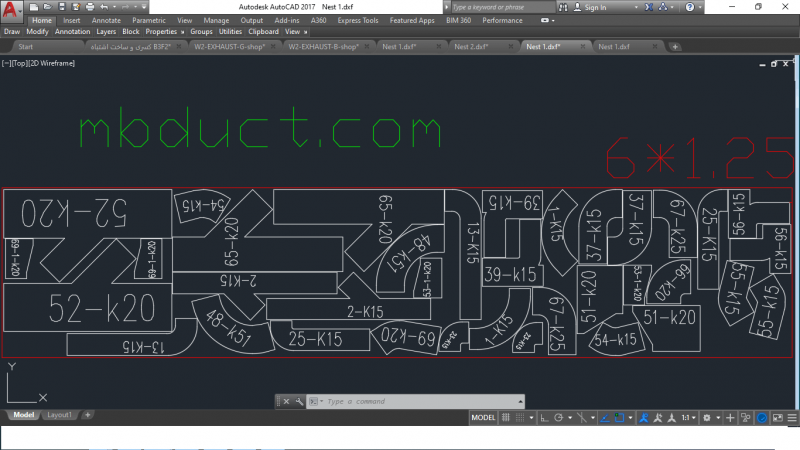

Utilizing specialized software, the desired ducts are laid out in a way that minimizes waste and is then nested on 6-meter sheets.

Subsequently, we proceed with plasma cutting using CNC technology, which ultimately contributes to increased speed and cost reduction in duct fabrication.

-

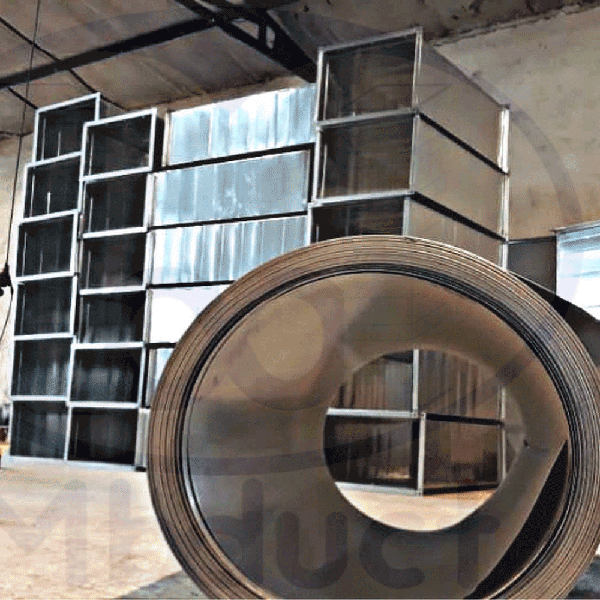

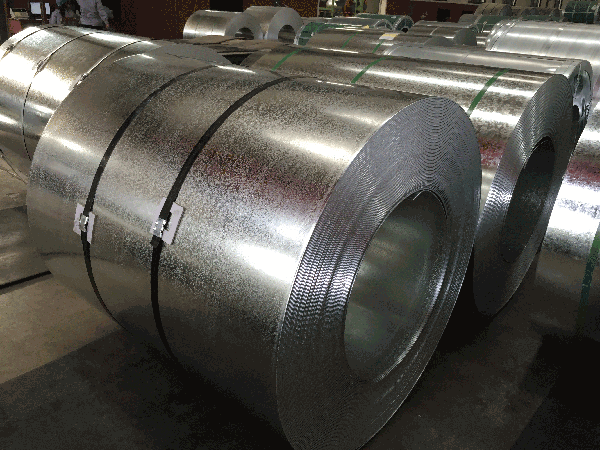

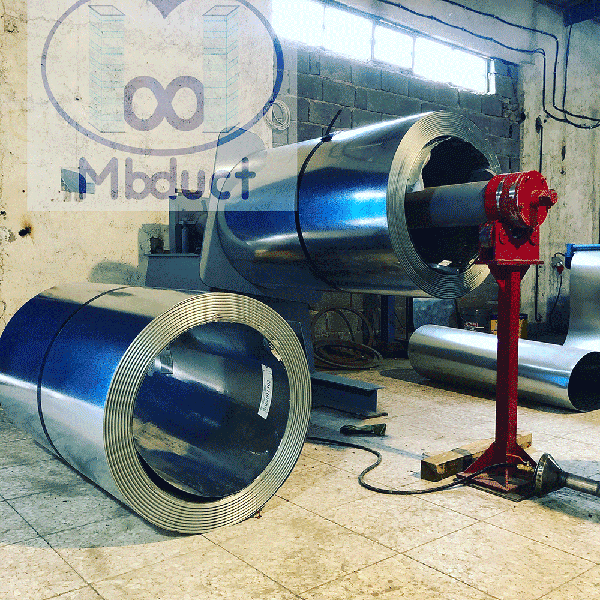

Use of Coil Sheet Instead of Flat Sheet

The MB Duct factory acquires galvanized sheet metal directly from the sheet production facility in coil form.

By utilizing specialized shape nesting software for cutting in various dimensions, as well as custom-sized sheet metal cutting, we significantly reduce waste, resulting in cost reduction for our esteemed clients.

TDF Duct Construction Method

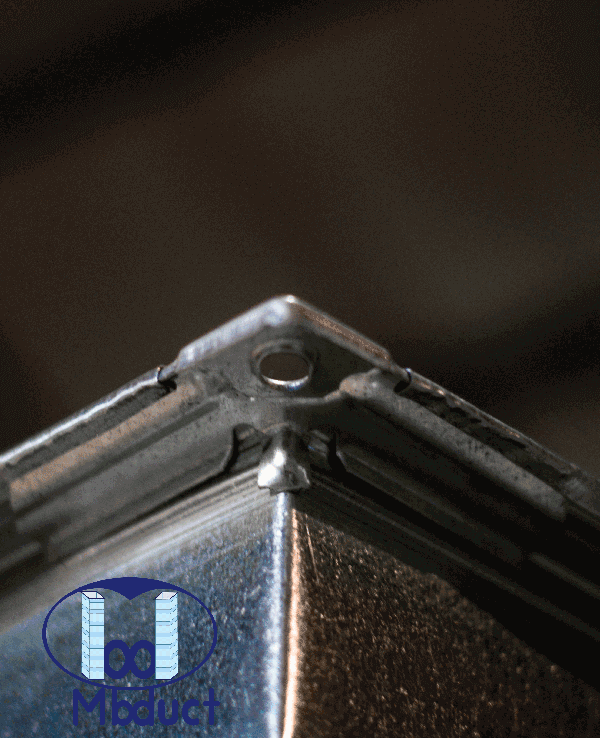

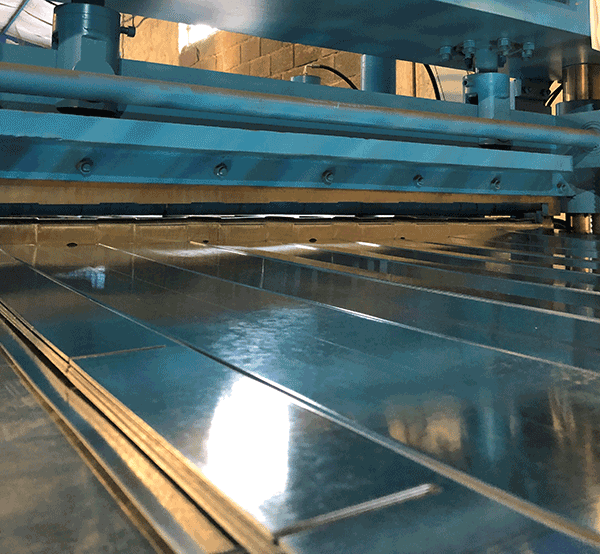

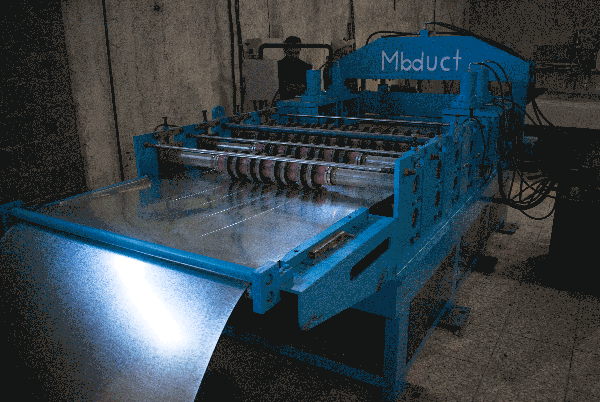

Before explaining the flanging process of the TDF duct flaps, it’s worth mentioning that the TDF system involves the creation of bright shadow lines using a dedicated roll forming machine.

This has a significant impact on reducing the dimensions of galvanized sheet metal by one to two sizes as calculated in the design blueprint.

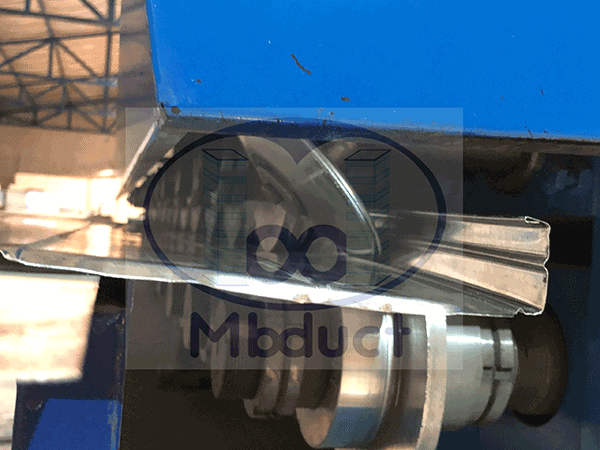

The operation of the TDF ventilation system, or self-flanged duct, is as follows: the flaps that are intended to be connected to each other have their ducts length increased by an additional 5 centimeters.

Of course, we ensure that neither the width nor the height of the flap dimensions change.

Now, we pass this additional 5 centimeters through the flanging machine..

During the process of passing through sixteen stages, it transforms into a flange, and there is no longer a need for iron or galvanized flanges.

Furthermore, due to the nature of the flange forming by the machine, the flange length is reduced from 5 centimeters to 3 centimeters.

Now, the duct that has been flanged at its ends needs to have its corners connected to each other.

This connection is made using components called corners.

These corners are made of galvanized material and result in a seamless appearance of the duct.

In these corners, there are holes where screws pass through from the inside, creating a connection between two ducts.

To connect the center sections of the ducts together, specialized clips are used.

Two duct pieces are securely fastened to each other using these clips and screws.

Furthermore, to prevent energy loss from the duct seams, a gasket tape is used between the connections of two flanges.

To seal the corner joints, mastics are employed.

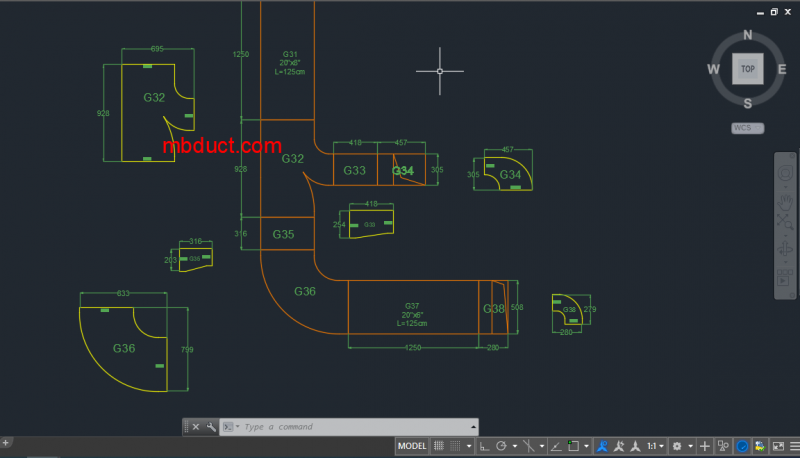

The Production and Delivery Process of TDF Ducts by Mbduct Company

In our facility, we strive to utilize state-of-the-art machinery and advanced equipment to provide innovative, efficient, and economically viable HVAC systems, including exhaust, positive pressure, fresh air supply, and parking ventilation, for residential, commercial, industrial, and hospital projects. Our experienced and skilled team works diligently to achieve these goals.

In this process, our engineering team first transforms the 3D design plans of the second-phase installations (using software such as Revit, 3Dmax, Rhino) into 2D CAD drawings.

Afterwards, the overall components and connections are coded, and each piece is assigned its unique code.

After CNC Plasma cutting, a specific code is marked on each piece of ductwork, and it is placed in the production line direction for assembly.

In this stage, two types of ducts are fabricated:

- TDF Duct (Self-flanged)

- TDC Duct (Galvanized Flanged)

After being prepared, the ducts are sent to their respective projects, and the installation team (*) can easily carry out the installation process in the fastest time and without any errors or issues, based on the drawings and codes marked on the ducts.

(*) The installation team can be either an independent contractor or the duct manufacturer themselves.

Continuing in sequence, we explain the stages of TDF fabrication:

-

Procurement of Sheet Rolls

Mbduct factory obtains galvanized sheet metal in the form of rolls directly from the sheet metal production plant.

This practice reduces costs for the esteemed client due to the custom cutting of the sheets, compared to purchasing pre-cut sheet metal.

2- Placement in the roll holder

3- The design on the sheet by the forming machine

4- CNC plasma cutting

5- The flange of the head itself

6- TDF duct edge, drawer and coupling

7- Loading and sending according to the list

General table comparing TDF and traditional ducts

| Time to build and install ducts | The weight of the constructed duct | U duct or corner support for installation (*) | Sealing tape | Hammer rivet for flange | Bolt and nut for flange | Connection with flange (iron angle) (*) | The thickness of the sheet to make the duct | |

| According to the project schedule | Fits the design | Fits the design | has it | has it | Fits the design | has it | Fits the design | Traditional duct |

| At least 1/2 schedule | 35 to 45% lighter than the design | At least 1/2 design | has it | does not have | Design number 1/3 | does not have | 1 to 2 sizes smaller than the design | Mbduct duct (TDF) |

(*) Considering the high cost of steel or aluminum corner angles for flange and U-ducts for support fabrication in traditional ducts, the absence of these components in Mbduct ducts leads to significant financial and time savings in large-scale construction projects, as well as for the esteemed client in the case of larger dimension ducts.

We proudly announce that Mbduct Company has the capacity to produce and deliver daily 150 to 200 square meters of TDF ducts (self-flanged) and TDC ducts (galvanized flanged).

In the end, you can contact us for more information and free consultation.

Quality is not accidental.